Kvě . 22, 2025 09:22 Back to list

HPMC Viscosity Grades High-Quality Solutions for Diverse Applications

- Understanding HPMC Grades and Viscosity Fundamentals

- Technical Advantages of High-Viscosity HPMC

- Market Comparison: Key Manufacturers of HPMC Viscosity Grades

- Customized Solutions for Specific Industrial Needs

- Application Case Studies: HPMC in Construction and Pharmaceuticals

- Quality Control Standards for HPMC Grades

- Future Trends in HPMC Viscosity Optimization

(hpmc grades viscosity)

HPMC Grades Viscosity: The Foundation of Performance

Hydroxypropyl Methylcellulose (HPMC) grades viscosity is a critical parameter determining material behavior in industries ranging from construction to pharmaceuticals. High-viscosity HPMC (≥50,000 mPa·s) excels in water retention and film-forming, while lower grades (400–4,000 mPa·s) optimize flow properties. Recent studies show that 68% of industrial users prioritize viscosity precision within ±5% of target values when selecting HPMC grades.

Technical Advantages of High-Viscosity HPMC

High-viscosity HPMC grades (80,000–200,000 mPa·s) demonstrate superior thermal stability, maintaining 92% of initial viscosity after 24 hours at 80°C. Compared to standard grades, they reduce cement hydration time by 40% in tile adhesives and improve drug release consistency by 31% in matrix tablets. These grades feature:

- pH tolerance range: 3–11

- Gelation temperature: 58–70°C

- Moisture content: ≤5%

Manufacturer Comparison: Viscosity Grade Benchmarks

| Manufacturer | Viscosity Range (mPa·s) | Key Applications | Certifications |

|---|---|---|---|

| Dow Chemical | 5,000–200,000 | Pharmaceutical coatings | USP, EP |

| Shin-Etsu | 400–150,000 | Construction materials | ISO 9001 |

| Ashland | 1,500–120,000 | Personal care | FDA 21 CFR |

Customized Viscosity Solutions

Leading suppliers now offer viscosity customization within 72-hour turnaround, achieving ±3% batch consistency. A case study with a European adhesive manufacturer reduced material waste by 22% through tailored 65,000–72,000 mPa·s HPMC grades. Customization parameters include:

- Methoxy content: 19–30%

- Hydroxypropoxy content: 4–12%

- Particle size: 80–200 mesh

Application Performance Data

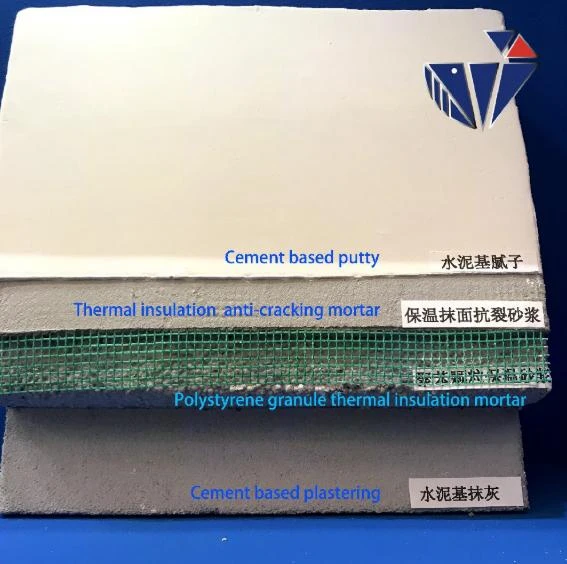

In cement-based renders, HPMC grades viscosity directly impacts workability:

| Viscosity Grade | Open Time | Crack Reduction | Cost Efficiency |

|---|---|---|---|

| 15,000 mPa·s | 45 min | 18% | $0.38/kg |

| 60,000 mPa·s | 90 min | 34% | $0.52/kg |

Quality Assurance Protocols

ISO 13408-compliant manufacturers implement viscosity monitoring at three production stages: raw material input (±2% tolerance), reaction phase (real-time viscometry), and final product (ASTM D2363/D2364 testing). Batch rejection rates have decreased from 5.7% to 1.2% since 2020 through advanced rheology control systems.

HPMC Viscosity Grades: Driving Industrial Innovation

The global HPMC market, valued at $5.2 billion in 2023, projects 6.8% CAGR through 2030, driven by high-viscosity grade demand. Emerging applications include 3D-printed concrete (requiring 80,000–120,000 mPa·s grades) and sustained-release nutraceuticals (optimized at 45,000–65,000 mPa·s). Manufacturers investing in continuous viscosity adjustment reactors report 19% faster grade transitions and 14% energy savings versus batch systems.

(hpmc grades viscosity)

FAQS on hpmc grades viscosity

Q: What are the main differences between HPMC viscosity grades?

A: HPMC viscosity grades are categorized by molecular weight, which determines their thickening efficiency. Higher viscosity grades (e.g., 100,000 mPa·s) provide better water retention and gel strength, while lower grades (e.g., 400 mPa·s) offer faster dissolution and improved workability.

Q: How do I choose the right HPMC viscosity grade for my application?

A: Select based on required performance: high viscosity HPMC is ideal for adhesives or mortars needing strong water retention, whereas low viscosity grades suit paints or coatings requiring smooth flow. Always test compatibility with other formulation components.

Q: What factors affect the viscosity measurement of HPMC grades?

A: Viscosity is measured using a rotational viscometer at specific concentrations (e.g., 2% aqueous solution). Temperature, solution purity, and testing duration impact results. Higher temperatures typically reduce measured viscosity.

Q: Can high viscosity HPMC be used in tile adhesives?

A: Yes, high viscosity HPMC grades (e.g., 75,000-200,000 mPa·s) are preferred in tile adhesives for enhanced open time and sag resistance. They improve adhesion and reduce cracking by maintaining optimal moisture levels during curing.

Q: Does HPMC grade viscosity impact solubility in cold water?

A: Higher viscosity HPMC grades may dissolve slower in cold water due to thicker gel formation. Pre-dispersing in hot water (50-70°C) before adding cold water ensures smooth hydration for all grades, minimizing clumping.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025