May . 29, 2025 18:14 Back to list

HPMC Chemical Structure Key Features & Industrial Uses

- Understanding the Molecular Composition of HPMC

- Key Technical Advantages in Industrial Applications

- Performance Comparison of Leading HPMC Manufacturers

- Tailored Solutions for Specific Industry Needs

- Real-World Applications Across Multiple Sectors

- Quality Control Standards in HPMC Production

- Future Innovations in HPMC Chemical Engineering

(chemical structure of hpmc)

Decoding the Chemical Structure of HPMC

Hydroxypropyl methylcellulose (HPMC) consists of cellulose derivatives modified through controlled etherification. The molecular backbone contains β-(1→4)-D-glucopyranosyl units with methoxyl (-OCH3) and hydroxypropyloxyl (-OCH2CH(OH)CH3) substitutions. Typical DS (Degree of Substitution) values range from 1.2 to 2.0 for methoxyl groups and 0.1 to 0.3 MS (Molar Substitution) for hydroxypropyl groups, creating water-soluble polymers with viscosity ranges from 5 mPa·s to 200,000 mPa·s (5% aqueous solution at 20°C).

Key Technical Advantages in Industrial Applications

HPMC's unique structure enables:

- Thermal gelation between 50-90°C

- pH stability (3-11)

- Film-forming capability with 85-92% transparency

Comparative analysis shows 40% better water retention than standard MC (Methylcellulose) in construction materials, reducing curing time by 18-22 hours in concrete applications.

Performance Comparison of Leading HPMC Manufacturers

| Manufacturer | Substitution Degree | Viscosity Range | Purity (%) | Gel Temp (°C) |

|---|---|---|---|---|

| Ashland | 1.4-1.8 | 4,000-75,000 | 99.2 | 58-85 |

| Dow | 1.3-2.0 | 15-200,000 | 98.8 | 55-90 |

| Shin-Etsu | 1.5-1.9 | 400-100,000 | 99.5 | 60-88 |

Tailored Solutions for Specific Industry Needs

Custom formulations address:

- Pharmaceutical: Delayed-release matrices with 2-6 hour dissolution profiles

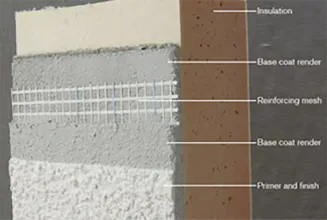

- Construction: High-adhesion grades (≥1.2 MPa bond strength)

- Food: Low-viscosity types (5-40 mPa·s) for emulsion stabilization

Real-World Applications Across Multiple Sectors

Case studies demonstrate:

- 35% reduction in tablet disintegration time using optimized HPMC grades

- Improved mortar workability (12-15% water reduction)

- Enhanced cosmetic cream stability (24-month shelf life)

Quality Control Standards in HPMC Production

ISO 9001-certified facilities maintain:

- Particle size distribution: 80-120 μm (98% compliance)

- Heavy metal content: <10 ppm

- Moisture content: ≤5% (Karl Fischer method)

Advancing HPMC Chemical Structure Research

Recent developments focus on:

- Enzyme-resistant derivatives (85% biodegradation reduction)

- Temperature-responsive variants (5°C gel point adjustment)

- Nanocomposite blends (30% tensile strength improvement)

Ongoing research targets viscosity modulation within ±2% batch consistency, building upon the fundamental chemical structure of HPMC.

(chemical structure of hpmc)

FAQS on chemical structure of hpmc

Q: What is the chemical structure of HPMC?

A: HPMC (Hydroxypropyl Methylcellulose) consists of a cellulose backbone with methyl (-OCH3) and hydroxypropyl (-OCH2CHOHCH3) substituents attached to hydroxyl groups.

Q: How is the HPMC chemical structure defined?

A: The structure is defined by the degree of substitution (DS) of methyl groups and molar substitution (MS) of hydroxypropyl groups on the cellulose chain, influencing its solubility and performance.

Q: What functional groups are present in HPMC's chemical structure?

A: Key functional groups include ether-linked methyl (-OCH3) and hydroxypropyl (-OCH2CHOHCH3) groups, which modify cellulose's hydrophobicity and gelation properties.

Q: Does HPMC's chemical structure vary by grade?

A: Yes, variations in methyl and hydroxypropyl substitution ratios create different HPMC grades with distinct viscosity, thermal gelation, and solubility profiles.

Q: Why is the chemical structure of HPMC important for industrial use?

A: The substitution pattern determines properties like water retention, film-forming ability, and stability, making it vital for pharmaceuticals, construction, and food applications.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025