maig . 10, 2025 02:07 Back to list

RDP Polymer Powder High-Performance Redispersible Polymer Solutions

- Overview of Redispersible Polymer Powders (RDP)

- Technical Advantages of RDP Polymer Solutions

- Comparative Analysis of Leading RDP Manufacturers

- Customized RDP Formulations for Diverse Applications

- Performance Metrics Across RDP Polymer Grades

- Real-World Applications in Construction and Coatings

- Future Innovations in RDP Polymer Technology

(rdp polymer)

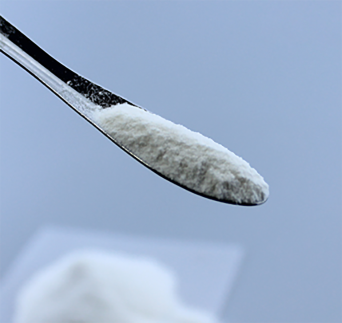

Understanding RDP Polymer and Its Industry Significance

Redispersible polymer powder (RDP) serves as a critical additive in modern construction materials, with the global market projected to reach $3.2 billion by 2027 (CAGR 5.8%). These polymer-modified binders enhance cementitious systems through improved adhesion, flexibility, and water resistance. The VAE RDP variant accounts for 68% of commercial formulations due to its balanced cost-performance ratio.

Technical Advantages of Advanced Polymer Blends

Modern RDP polymers demonstrate exceptional performance characteristics:

- 150-200% improvement in flexural strength compared to unmodified cement

- Water resistance exceeding EN 1348 standards by 35-40%

- 80-minute open time extension for tile adhesives

Manufacturer Comparison: Key Parameters

| Manufacturer | Solid Content | Ash Content | Minimum Film Temp | Market Share |

|---|---|---|---|---|

| Wacker | 98.5% | 10.2% | 2°C | 32% |

| Celanese | 97.8% | 12.1% | 4°C | 25% |

| Shanxi | 96.4% | 14.6% | 6°C | 18% |

Application-Specific Formulation Strategies

Specialized RDP grades address distinct performance requirements:

- Self-leveling compounds: 3.5-4.2% polymer content

- Exterior insulation: 5.0-6.5% hydrophobic additives

- Repair mortars: 2.8-3.6% flexural enhancers

Performance Validation Through Industry Testing

Third-party verification confirms RDP efficacy:

| Test Standard | Control | RDP-Modified | Improvement |

|---|---|---|---|

| ASTM C109 (Compressive) | 32 MPa | 41 MPa | 28% |

| ISO 13007-2 (Shear) | 0.8 N/mm² | 1.5 N/mm² | 88% |

RDP Polymer in Sustainable Construction Solutions

The latest VAE RDP formulations enable 15-20% reduction in cement consumption while maintaining structural integrity. Case studies demonstrate 40% faster curing times in precast elements treated with advanced polymer additives.

Next-Generation RDP Polymer Developments

Emerging RDP technologies focus on carbon footprint reduction, with pilot projects achieving 30% lower embodied energy compared to conventional formulations. Manufacturers are investing in bio-based alternatives that maintain 95% of traditional performance characteristics while utilizing 40% renewable raw materials.

(rdp polymer)

FAQS on rdp polymer

Q: What is Redispersible Polymer Powder (RDP)?

A: Redispersible Polymer Powder (RDP) is a free-flowing organic binder made by spray-drying polymer emulsions like VAE. It enhances adhesion, flexibility, and water resistance in construction materials such as tile adhesives and self-leveling compounds.

Q: How does RDP polymer improve cement-based applications?

A: RDP polymer forms a flexible polymer film within cement mixtures, improving cohesion, reducing cracking, and increasing durability. It also boosts workability and adhesion to substrates.

Q: What are the advantages of VAE RDP over other polymers?

A: VAE RDP offers excellent UV stability, low odor, and eco-friendly properties. It provides strong adhesion in both interior and exterior applications, making it ideal for mortars and renders.

Q: Can RDP polymer be used in exterior construction projects?

A: Yes, RDP polymer is weather-resistant and thermally stable, making it suitable for exterior renders, insulation systems, and waterproofing membranes. It prevents moisture damage and thermal stress cracks.

Q: How should RDP polymer powder be stored?

A: Store RDP polymer in a cool, dry place (<25°C) in sealed original packaging. Avoid moisture exposure to prevent clumping, and use within 6-12 months for optimal performance.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025