dec . 17, 2024 07:29 Back to list

Exploring RDP Polymer Innovations for Advanced Applications in Material Science

Exploring RDP Polymer A Key Player in Modern Polymer Science

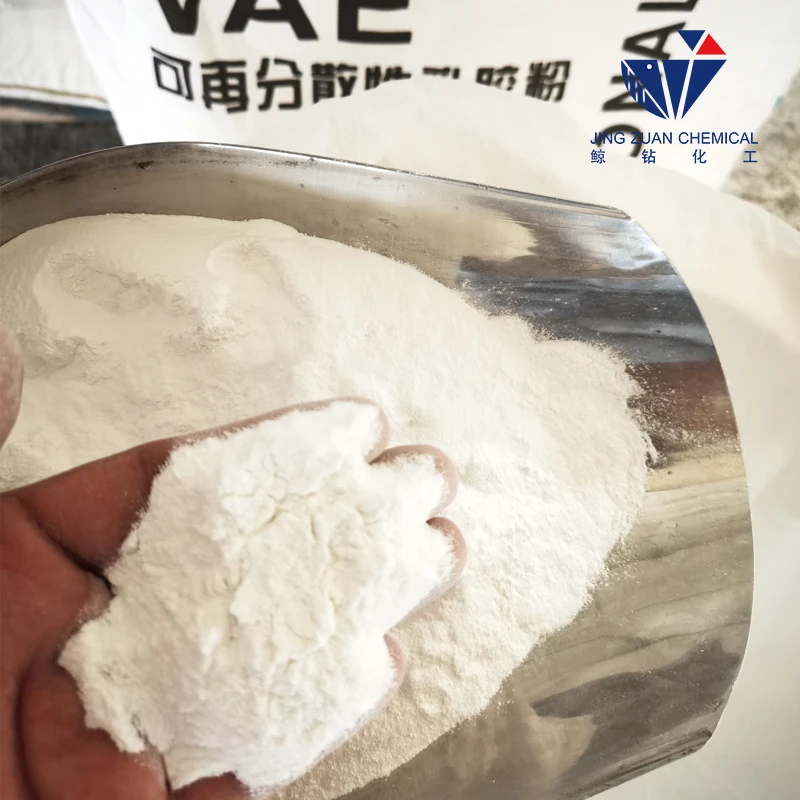

In recent years, advancements in polymer science have led to the development of numerous materials that possess unique properties and applications. One such material is the RDP polymer, or Redispersible Polymer Powder. This innovative polymer has garnered significant interest due to its versatility and range of applications in various industries, particularly in construction, coatings, and adhesives.

RDP polymer is created by drying a polymer emulsion into a powder form. When mixed with water, it redisperses back into an emulsion, allowing for easy incorporation into a wide array of formulations. This unique property distinguishes RDP polymers from other polymer powders, making them particularly advantageous in diverse applications.

Exploring RDP Polymer A Key Player in Modern Polymer Science

Moreover, RDP polymers facilitate improved workability and consistency in construction materials. They help maintain the necessary properties of the mix during transportation and application, ensuring that the materials perform well and meet the required standards once set. This is particularly important in large-scale construction projects where quality control is critical.

rdp polymer

In the realm of coatings, RDP polymers contribute to the development of high-performance paints and finishes. They enhance the mechanical properties of the coatings, providing improved adhesion to various substrates and resistance to weathering and UV degradation. As a result, buildings and structures can maintain their aesthetic appeal and structural integrity for extended periods, reducing the need for frequent maintenance and repainting.

In addition to their applications in construction and coatings, RDP polymers have found use in the adhesive industry. Their incorporation into adhesive formulations enhances bonding strength, flexibility, and moisture resistance. This is particularly beneficial in applications requiring durable and resilient adhesive joints, such as in woodwork, furniture manufacturing, and automotive assembly.

The environmental impact of RDP polymers is also worth noting. Many RDP emulsions are based on sustainable raw materials and are designed to reduce the carbon footprint of the products they are used in. Additionally, RDPs often facilitate the reduction of water consumption in formulations, aligning with the industry's growing emphasis on sustainability and eco-friendliness.

As researchers and developers continue to explore the potential of RDP polymers, we can expect further innovations and enhancements in their properties and applications. Combining RDP polymers with other materials or advancing their formulation processes could unlock new possibilities, making them even more valuable in various industrial applications.

In conclusion, RDP polymers represent a remarkable advancement in polymer technology. Their versatility allows for improved performance in construction materials, coatings, and adhesives, making them indispensable in modern applications. As the demand for high-performance, sustainable materials continues to rise, RDP polymers are poised to play an increasingly crucial role in the future of polymer science and industry. Through ongoing research and innovation, we can anticipate the evolution of RDP polymers, solidifying their status as a key player in the world of materials science.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025