dec . 24, 2024 23:50 Back to list

Exploring the Viscosity Characteristics of HPMC and Its Applications in Various Industries

Understanding HPMC Viscosity An Essential Parameter in Pharmaceutical Formulations

Hydroxypropyl methylcellulose (HPMC) is a cellulose derivative widely used in the pharmaceutical industry due to its unique viscometric properties. One of the critical characteristics that dictate its functionality in various formulations is its viscosity. The viscosity of HPMC plays a significant role in determining the texture, stability, and release profiles of pharmaceutical products, making it an essential parameter in formulation development.

What is HPMC?

HPMC is a semi-synthetic polymer derived from cellulose. Its structure consists of hydroxyl and methoxy groups, which confer solubility and viscosity-enhancing properties. HPMC can be classified based on its hydroxypropyl and methoxy content, influencing not only the viscosity but also the gelation and thickening properties. This versatility makes HPMC suitable for a wide variety of applications, including tablets, capsules, topical formulations, and even food products.

Importance of Viscosity

Viscosity is a measure of a fluid’s resistance to flow. In the case of HPMC, its viscosity can be influenced by several factors, including molecular weight, concentration, and the specific solvent system used. The viscosity of HPMC solutions can vary widely, and this variability is key to its performance in different applications.

In pharmaceutical formulations, viscosity impacts several critical attributes

1. Flow Properties The viscosity of HPMC influences the flow behavior of the product during manufacturing processes, including mixing, casting, and filling. Higher viscosity solutions often lead to better handling properties, reducing the potential for segregation during processing.

2. Stability Viscosity plays an essential role in enhancing the stability of suspensions and emulsions. The thickening effect of HPMC can prevent the settling of suspended particles and enhance the overall product homogeneity.

3. Release Profiles In controlled-release formulations, the viscosity of HPMC can modulate the rate at which active ingredients are released. The thickness of the gel formed around the drug can slow down diffusion, providing sustained release and improved therapeutic effects.

Measuring HPMC Viscosity

The viscosity of HPMC is commonly measured using rheological methods. These measurements can be taken using a variety of viscometers or rheometers, which provide data on how the viscosity changes with shear rate, temperature, and concentration. The relationship between shear rate and viscosity is crucial for understanding how HPMC will behave under various processing conditions and during storage.

Factors Affecting Viscosity

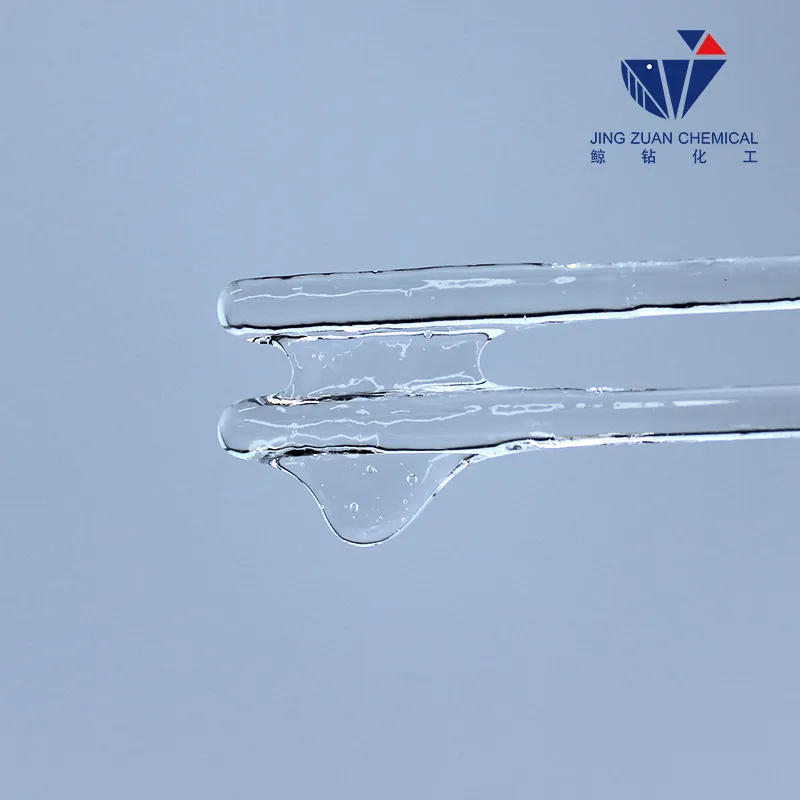

hpmc viscosity

Several factors can affect the viscosity of HPMC solutions

- Molecular Weight Generally, as the molecular weight of HPMC increases, its viscosity also increases. High molecular weight HPMC is often sought in applications requiring greater thickness or gel-like properties.

- Concentration The concentration of HPMC in a solution directly impacts its viscosity. As the concentration increases, so does the interaction between polymer chains, leading to a rise in resistance to flow.

- Temperature Temperature changes can significantly alter the viscosity of HPMC solutions. Most HPMC products exhibit a decrease in viscosity with increasing temperature, which is an essential consideration during processing and storage.

- pH and Ionic Strength The environment’s pH and ionic strength can influence the solubility and consequently the viscosity of HPMC. Formulators must account for these factors when designing a product for specific applications.

Applications of HPMC Viscosity

Due to its adaptable viscosity characteristics, HPMC finds a wide range of applications

- Pharmaceutical Formulations HPMC is used as a binder, thickener, and stabilizer in tablets and topical ointments.

- Food Industry In food formulations, HPMC provides thickening and gelling properties, enhancing texture and mouthfeel.

- Cosmetics HPMC is employed in cosmetic formulations for its ability to stabilize emulsions and improve the smoothness of cream and lotion products.

Conclusion

In conclusion, HPMC viscosity is a pivotal parameter that influences the performance and efficacy of pharmaceutical formulations. By understanding the factors that affect viscosity and how to measure it, formulators can design products that meet specific therapeutic objectives. The versatility of HPMC not only makes it an invaluable component in pharmaceuticals but also in various other industries, showcasing its broad applicability and importance. As research continues to advance, the understanding of HPMC’s viscosity properties will undoubtedly lead to innovative formulation strategies and improved product outcomes.

-

Why HPMC is a Key Additive in Wall Putty Formulations

NewsAug.05,2025

-

Redispersible Powder in Decorative Renders: Function Meets Finish

NewsAug.05,2025

-

Redispersible Powder for Interior Wall Putty: Smooth Results Every Time

NewsAug.05,2025

-

HPMC’s Water Retention Capacity in Dry Mortar Applications

NewsAug.05,2025

-

HPMC Factory Contributions to Liquid Detergents

NewsAug.05,2025

-

How HPMC Factory Products Change Detergent Textures

NewsAug.05,2025