дек. . 26, 2024 17:01 Back to list

hpmc grades

Understanding HPMC Grades A Guide to Hydroxypropyl Methylcellulose

Hydroxypropyl Methylcellulose (HPMC) is a versatile and widely used cellulose ether with applications across various industries, from pharmaceuticals to food and construction. HPMC is derived from cellulose, the natural polymer found in the cell walls of plants. By modifying cellulose with hydroxypropyl and methyl groups, HPMC is created to possess unique properties that make it suitable for multiple uses. This article delves into the different HPMC grades, their characteristics, and applications.

What is HPMC?

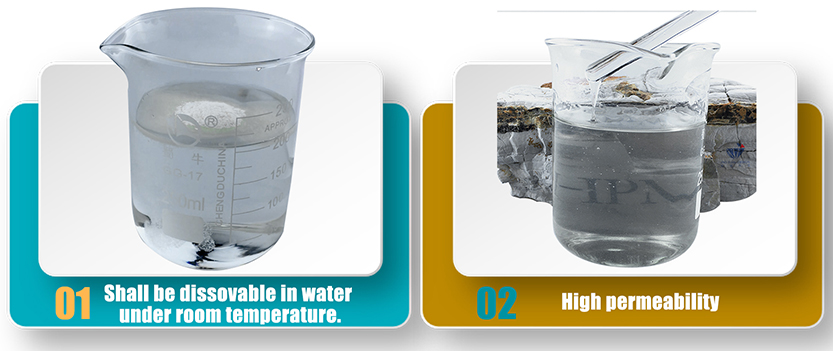

HPMC is a white to off-white powder that is odorless and tasteless. It is soluble in water, forming a viscous solution that can be used as a thickening agent, binder, or film-forming agent. The degree of substitution, viscosity, and polymer molecular weight contribute to the categorization of HPMC into various grades. The differences in these properties dictate the specific applications of each grade.

HPMC Grades and Their Properties

1. Low Viscosity Grades Low viscosity HPMC grades are characterized by their quick solubility and lower thickening capabilities. These grades are often used in applications requiring rapid dispersion, such as in the manufacturing of instant foods and beverages. They help improve the texture of products without significantly altering their flow properties.

2. Medium Viscosity Grades Medium viscosity HPMC grades strike a balance between thickening and solubility. They are versatile and can be used in a wide array of applications, including pharmaceutical formulations, cosmetics, and personal care products. Their moderate viscosity makes them effective as binders in tablet formulations and stabilizers in emulsions.

3. High Viscosity Grades High viscosity HPMC grades possess excellent thickening properties and are ideal for use in applications that require robust gel formation. These grades are commonly found in construction materials such as tile adhesives and joint compounds, where they provide superior workability and adhesion. In the pharmaceutical industry, high viscosity HPMC helps improve the sustained release of active ingredients in formulations.

hpmc grades

Applications of HPMC

HPMC's diverse range of grades allows it to find applications in numerous fields

- Pharmaceuticals HPMC is extensively used as a binder in tablet formulations and as a controlled-release agent. Its ability to form gels also makes it an ideal candidate for ocular solutions and hydrophilic matrices.

- Food Industry In food applications, HPMC acts as a thickener, emulsifier, and stabilizer. It is commonly used in bakery products, sauces, dairy items, and low-fat offerings, enhancing texture and preventing syneresis.

- Construction In construction, HPMC is vital in cement-based products, enhancing their mechanical properties and workability. It helps in water retention, preventing premature drying of mortar and plaster.

- Cosmetics and Personal Care HPMC is employed in various cosmetic formulations, including lotions, creams, and gels, where it acts as a thickener and stabilizer. Its ability to form films is beneficial in hair care products.

Conclusion

Understanding HPMC grades is essential for industries that seek to leverage its unique properties for specific applications. By selecting the right grade, manufacturers can enhance product performance, improve texture, and ensure stability. As demand for natural and versatile ingredients continues to grow, HPMC remains a key component in formulating innovative solutions across multiple sectors, ensuring its relevance in contemporary markets. Whether in pharmaceuticals, food, construction, or cosmetics, HPMC's diverse functionalities make it an invaluable asset for manufacturers worldwide.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025