ное. . 17, 2024 20:39 Back to list

how to dissolve hpmc in water

How to Dissolve HPMC in Water A Comprehensive Guide

Hydroxypropyl methylcellulose (HPMC) is a versatile cellulose ether widely used in various industries such as pharmaceuticals, food, construction, and cosmetics. Its unique properties, including excellent viscosity, gel formation, and adhesive characteristics, make it an essential ingredient in many formulations. One of the most critical steps in utilizing HPMC is its proper dissolution in water. This article will guide you through the process of dissolving HPMC effectively, ensuring optimal performance in your applications.

Understanding HPMC

Before diving into the dissolution process, it’s essential to understand what HPMC is and how it behaves in water. HPMC is a non-ionic, water-soluble polymer derived from natural cellulose. When mixed with water, HPMC forms a viscous gel with thickening and stabilizing properties. The dissolution process can be affected by various factors, including the viscosity grade of HPMC, water temperature, and the method of mixing.

Choosing the Right HPMC Grade

HPMC comes in various viscosity grades, which correspond to the thickness of the solution produced. The choice of grade depends on the application. For instance, pharmaceutical formulations may require a high-viscosity grade for controlled release, while food applications may only need a low-viscosity grade for thickening sauces. Make sure to select the appropriate grade before proceeding with dissolution.

Equipment and Materials Needed

To dissolve HPMC in water effectively, you will need

1. HPMC Powder The specific grade based on your needs. 2. Water Use distilled or deionized water to avoid impurities. 3. Mixing Equipment A mechanical stirrer or a high-shear mixer is recommended for efficient mixing. 4. Heating Element (optional) A water bath or heating plate to maintain optimal temperatures.

Step-by-Step Dissolution Process

how to dissolve hpmc in water

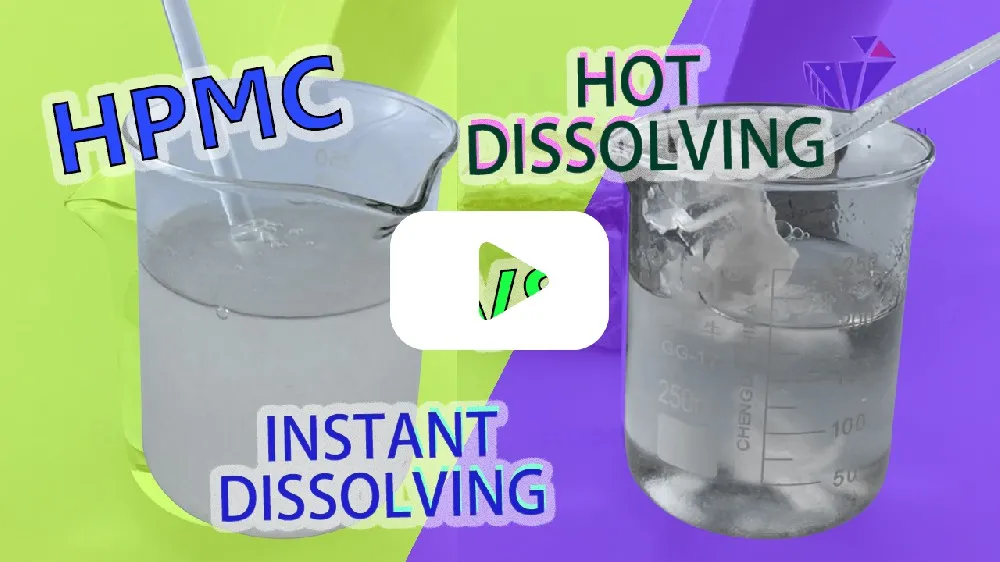

1. Prepare the Water - Measure the required amount of distilled or deionized water based on your formulation needs. It is recommended to use warm water (around 60-80°C) to facilitate faster dissolution, although HPMC can dissolve in cold water as well.

2. Add HPMC Slowly - Gradually sprinkle the HPMC powder into the water while continuously stirring. Avoid adding it all at once, as this can lead to clumping and incomplete dissolution. The powder should be added in a thin stream to ensure even distribution.

3. Stirring - Use a mechanical stirrer or high-shear mixer to blend the HPMC and water thoroughly. Continue stirring for at least 30 minutes to an hour. The intensity and duration of stirring play a crucial role in achieving a uniform solution. If you observe any lumps or undissolved particles, increase the stirring speed.

4. Heating (if necessary) - If you started with cold water, heating it can enhance the dissolution rate. Maintain the temperature between 60-80°C as you stir. Do not allow the solution to reach boiling, as this could denature the polymer and affect its properties.

5. Cooling and Final Mixing - Once the HPMC is fully dissolved, allow the solution to cool down to room temperature while continuing to stir gently. This helps achieve a stable viscosity and prevents any potential thickening due to cooling.

6. Quality Checks - After cooling, visually inspect the solution for clarity and uniformity. There should be no visible lumps or sediments. A smooth, well-mixed solution indicates successful dissolution.

Troubleshooting Common Issues

- Clumping or Lumps This typically occurs when HPMC is added too quickly or to low-temperature water. Always add the powder slowly and consider pre-wetting the powder before mixing. - Inconsistent Viscosity This can result from inadequate stirring or incomplete dissolution. Ensure thorough mixing and be patient during the process.

Conclusion

Dissolving HPMC in water may require some technique and patience, but following these steps will help you achieve the desired results. Proper dissolution is crucial for ensuring that HPMC functions effectively in its intended application, whether it’s for pharmaceuticals, food products, or construction materials. By selecting the right grade, maintaining optimal conditions, and employing efficient mixing, you can maximize the benefits of HPMC in your formulations.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025