Ліст . 06, 2024 00:17 Back to list

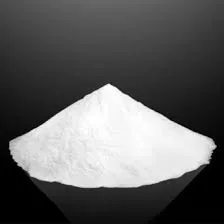

building coating adhesive hpmc

The Role of HPMC in Building Coating Adhesives

In the world of construction and building materials, the importance of high-performance adhesives cannot be overstated. Among the various types of additives used to enhance adhesive properties, Hydroxypropyl Methylcellulose (HPMC) has emerged as a crucial component in the formulation of building coating adhesives. This article explores the significance of HPMC in improving the performance of these adhesives, particularly in terms of workability, adhesion, and durability.

The Role of HPMC in Building Coating Adhesives

Another vital role of HPMC in building coatings is its influence on adhesion performance. Adhesives formulated with HPMC exhibit improved bonding properties to a variety of substrates, including concrete, wood, and metal. This is particularly important in the construction industry, where different materials must be effectively adhered to one another to ensure structural integrity. HPMC helps create a strong interfacial bond between the adhesive and the substrate, enhancing the overall adhesion strength and providing a durable solution for construction needs.

building coating adhesive hpmc

Moreover, HPMC serves as a crucial factor in the drying and curing processes of building coating adhesives. It aids in controlling water retention within the adhesive mixture, allowing for optimal hydration of the cement particles in cement-based adhesives. This controlled water retention leads to improved curing rates and helps prevent issues such as cracking or shrinkage that can occur when adhesives dry too quickly. The balanced moisture retention facilitated by HPMC results in a stronger, more reliable bond once the adhesive has fully cured.

In addition to these technical benefits, the use of HPMC in building coating adhesives is favorable from an environmental perspective. As a versatile and biodegradable cellulose derivative, HPMC aligns with the growing trend towards sustainable construction practices. It offers the capability to produce low VOC (volatile organic compound) adhesives, which are better for indoor air quality and have a reduced environmental impact.

In summary, Hydroxypropyl Methylcellulose (HPMC) is an indispensable additive in the formulation of building coating adhesives. Its ability to enhance workability, improve adhesion performance, and control moisture retention makes it a popular choice among manufacturers and construction professionals alike. As the construction industry continues to evolve, the demand for high-performing and environmentally friendly materials like HPMC will undoubtedly increase, paving the way for more sustainable building practices. By harnessing the benefits of HPMC, construction professionals can ensure that their adhesive products meet the rigorous demands of modern construction while contributing to a healthier planet.

-

The Widespread Application of Redispersible Powder in Construction and Building Materials

NewsMay.16,2025

-

The Widespread Application of Hpmc in the Detergent Industry

NewsMay.16,2025

-

The Main Applications of Hydroxyethyl Cellulose in Paints and Coatings

NewsMay.16,2025

-

Mortar Bonding Agent: the Key to Enhancing the Adhesion Between New and Old Mortar Layers and Between Mortar and Different Substrates

NewsMay.16,2025

-

HPMC: Application as a thickener and excipient

NewsMay.16,2025

-

Hec Cellulose Cellulose: Multi functional dispersants and high-efficiency thickeners

NewsMay.16,2025