Dek . 19, 2024 21:33 Back to list

hpmc glass transition temperature

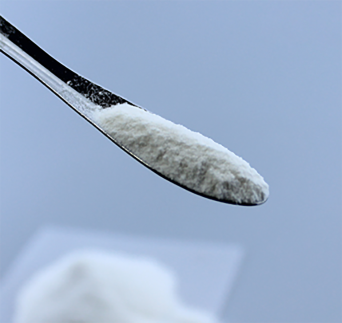

Understanding the Glass Transition Temperature in HPMC

Hydroxypropyl methylcellulose (HPMC) is a cellulose derivative widely used in pharmaceutical formulations, food products, and various industrial applications. One of its critical properties is its glass transition temperature (Tg), which significantly influences its physical characteristics and performance. This article explores the concept of glass transition temperature in HPMC and its implications in various applications.

What is Glass Transition Temperature?

Glass transition temperature is defined as the temperature at which an amorphous material, such as HPMC, transitions from a brittle glassy state to a more flexible rubbery state. Below Tg, the polymer chains are rigid and immobilized, preventing them from moving freely. Above Tg, the molecular motion increases, leading to greater flexibility and a range of mechanical properties. This transition is crucial for understanding how HPMC behaves under different temperature conditions and how it can be processed and utilized effectively.

The Importance of HPMC's Glass Transition Temperature

The glass transition temperature of HPMC is significant for several reasons. Firstly, it influences the solubility and swelling behavior of the polymer in various solvents, particularly in pharmaceutical applications where HPMC is used as a film-forming agent, thickener, or binder. The Tg can determine the release profile of drugs from HPMC-based matrices, impacting the overall efficacy and bioavailability of the medication.

Secondly, in food applications, the glass transition temperature affects the texture and stability of products. For instance, the Tg of HPMC can dictate the moisture uptake in food preparations, influencing shelf life and quality. A thorough understanding of Tg enables manufacturers to optimize formulations for desired properties, affecting consumer acceptability and product performance.

Factors Affecting Tg in HPMC

hpmc glass transition temperature

Several factors influence the glass transition temperature of HPMC. The degree of substitution and molecular weight are two of the most vital parameters. HPMC grades with different levels of hydroxypropyl and methoxy substitutions exhibit varied Tg, which can be tailored for specific applications. Additionally, the presence of plasticizers can lower the Tg, offering enhanced flexibility and processability while maintaining the desired characteristics of the polymer.

The processing conditions during the preparation of HPMC formulations also play a role in Tg. Thermal history, humidity, and the presence of additives or fillers can shift the Tg, necessitating careful consideration during formulation development.

Implications of Tg in Applications

In pharmaceutical formulations, the Tg influences drug release rates, stability, and formulation efficacy. For controlled-release systems, a precise understanding of Tg is essential to ensure consistent and predictable drug delivery.

In food science, the control over Tg can lead to improved texture and mouthfeel in food products, enhancing consumer experience. For instance, HPMC is often employed in gluten-free baking as a structure-forming agent; understanding its Tg can lead to superior texture and moisture retention.

Conclusion

In conclusion, the glass transition temperature of hydroxypropyl methylcellulose is more than just a number; it serves as a pivotal point that dictates the material's performance across various industries. By understanding and controlling Tg, researchers and manufacturers can enhance the physical properties of HPMC, leading to improved applications in pharmaceuticals, food products, and beyond. As science continues to advance, the potential for tailored HPMC applications will only grow, making the study of its glass transition temperature an essential area of focus.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025