نوفمبر . 09, 2024 17:09 Back to list

Exploring the Benefits of Dispersible Polymer Powders in Various Applications

The Role and Significance of Dispersible Polymer Powders in Modern Applications

In recent years, the demand for high-performance materials has surged across various industries, driving innovations in polymer technology. One notable advancement is the development of dispersible polymer powders, which have gained significant traction due to their versatility and wide range of applications. These polymer powders offer unique properties that enhance the performance of products in construction, adhesives, coatings, and more.

What are Dispersible Polymer Powders?

Dispersible polymer powders are fine powders made from polymers that can be easily dispersed in water to form stable emulsions or suspensions. They are typically produced through a process called spray-drying, which involves the conversion of a liquid polymer solution into a powder form. This transformation not only improves the handling and storage of the material but also enables easy incorporation into various formulations.

These powders come in different grades and types, each tailored for specific uses. Common examples include polyvinyl acetate (PVA), styrene butadiene latex (SBR), and acrylic-based polymers. Their ability to combine easily with other materials makes them a popular choice across different sectors.

Advantages of Dispersible Polymer Powders

1. Improved Performance Dispersible polymer powders provide superior adhesion, flexibility, and water resistance compared to traditional binder systems. This makes them ideal for applications requiring durable and long-lasting solutions.

2. Ease of Use They can be easily mixed with water and other additives, simplifying the production process. This enables manufacturers to create uniform and high-quality formulations without the need for extensive equipment.

3. Environmentally Friendly Many dispersible polymer powders are formulated to be low in volatile organic compounds (VOCs), making them a more environmentally conscious choice. This is particularly important as industries seek to comply with stricter environmental regulations.

4. Customization The wide range of available polymer types allows for the customization of properties, such as thickness, viscosity, and adhesion strength, to meet specific performance requirements. This flexibility is a key advantage for manufacturers looking to differentiate their products in the marketplace.

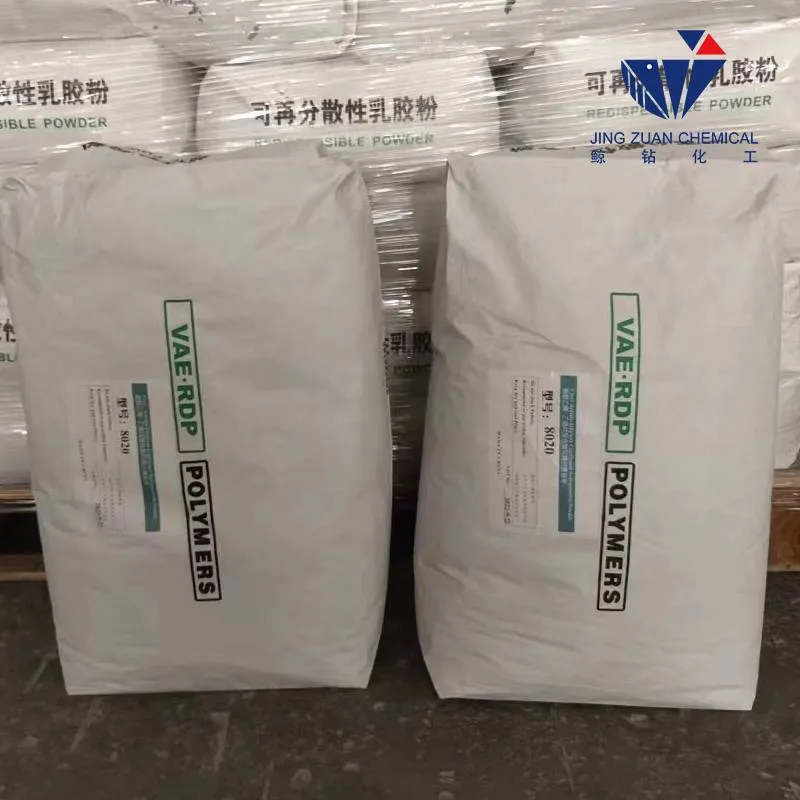

dispersible polymer powder

Applications in Various Industries

Dispersible polymer powders are widely used across multiple industries. In the construction sector, they are primarily utilized as additives in cement and mortar formulations to enhance bond strength, flexibility, and workability. These characteristics are essential for creating robust and resilient structures capable of withstanding environmental challenges.

In the adhesives industry, these powders bolster the performance of adhesives and sealants. By improving adhesion properties and decreasing drying time, dispersible polymer powders contribute significantly to the efficiency and durability of adhesive applications.

Additionally, the coatings industry benefits from these polymers, as they assist in producing paint and coating formulations that provide excellent coverage and resistance to weathering. Their ability to form a strong film when dry ensures that coated surfaces maintain their aesthetic and functional qualities over time.

Future Trends

As the demand for sustainable and high-performance materials continues to grow, the future of dispersible polymer powders looks promising. Innovations in polymer chemistry are likely to lead to the development of new grades that boast even better performance characteristics. Furthermore, the increasing emphasis on green building practices and environmentally friendly products is expected to drive the adoption of low-VOC dispersible polymer powders.

Another trend worth noting is the integration of smart technologies within polymer formulations. The incorporation of nanomaterials and self-healing capabilities could significantly enhance the properties of dispersible polymer powders, making them even more valuable across various applications.

Conclusion

Dispersible polymer powders stand at the forefront of modern material technology, offering solutions that meet the evolving needs of various industries. Their advantageous properties combined with their versatility make them essential components in construction, adhesives, coatings, and beyond. As research and development continue to advance, we can expect these polymers to play an increasingly important role in creating innovative, high-performance, and sustainable products for the future. The journey of dispersible polymer powders is just beginning, and their potential is boundless.

-

Unlocking the Benefits of HPMC Products: A Gateway to Versatile Applications

NewsAug.07,2025

-

Unleashing the Potential of HPMC Ashland: A Comprehensive Look

NewsAug.07,2025

-

Tile Bonding Cellulose: The Key to Superior Adhesion and Durability

NewsAug.07,2025

-

Hydroxypropyl Methylcellulose Powder: The Versatile Component in Modern Pharmaceuticals

NewsAug.07,2025

-

Hydroxyethyl Cellulose: The Versatile Solution for Various Industries

NewsAug.07,2025

-

Hydroxyethyl Cellulose (HEC): The Versatile Polymer for Various Applications

NewsAug.07,2025