ኅዳር . 16, 2024 03:34 Back to list

china hpmc-hydroxypropyl methyl cellulose manufacturer

HPMC A Versatile Compound from China’s Leading Manufacturers

Hydroxypropyl Methyl Cellulose (HPMC) is a cellulose ether widely used in the food, pharmaceutical, and construction industries. It is derived from natural cellulose sources, making it a biodegradable and environmentally friendly compound. With the increasing demand for high-quality HPMC, China has emerged as a leading manufacturer, producing a variety of grades to meet the diverse needs of global markets.

Understanding HPMC

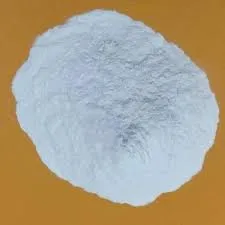

HPMC is a non-ionic polymer that exhibits unique properties such as water solubility, thickening, and film-forming abilities. This compound is white or off-white powder that dissolves in cold water to form a clear or slightly opalescent solution. Its neutral pH and excellent stabilizing properties make it a popular choice across various applications.

In the food industry, HPMC is often utilized as a thickener, emulsifier, and stabilizer in products like sauces, dressings, and baked goods. It enhances texture and prevents the separation of ingredients, ensuring a consistent product. In pharmacy, HPMC serves as an excipient in drug formulations, allowing for controlled release and efficient absorption of active ingredients. Its role as a binder, disintegrant, and film-coating agent adds to its versatility in pharmaceutical applications. Additionally, in the construction industry, HPMC is used in cement and drywall compounds, enhancing workability and water retention.

China’s HPMC Manufacturing Landscape

China's dominance in the HPMC market is attributed to its advanced manufacturing techniques, vast raw material availability, and competitive pricing. The country is home to several prominent HPMC manufacturers who adhere to international quality standards and certifications.

These manufacturers invest heavily in research and development, ensuring their products meet the specific needs of their customers. The production process involves etherification of cellulose, which is derived from natural sources such as cotton or wood pulp. This process is carefully controlled to ensure the desired degree of substitution, viscosity, and solubility of the final product.

china hpmc-hydroxypropyl methyl cellulose manufacturer

Moreover, Chinese HPMC manufacturers are leveraging modern technologies to improve production efficiency and reduce environmental impact. Many companies have adopted green production practices, utilizing sustainable raw materials and minimizing waste through recycling and reusing industrial by-products.

Quality Assurance and Compliance

One of the key factors that set Chinese HPMC manufacturers apart is their commitment to quality assurance. Many of these companies comply with international standards such as ISO 9001 and GMP (Good Manufacturing Practices). This adherence to quality ensures that the HPMC produced is safe, reliable, and suitable for diverse applications.

Furthermore, Chinese manufacturers often conduct rigorous testing of their products before they reach the market. This testing includes assessments of viscosity, solubility, and thermal stability, among other properties. By ensuring that their products meet specified standards, manufacturers can build trust with their clients and maintain a strong position in the global market.

Global Demand and Future Prospects

The demand for HPMC is forecasted to grow significantly due to the expanding applications in various industries. The construction sector, in particular, is expected to be a major driver of this growth, fueled by ongoing infrastructure projects and urban development initiatives worldwide.

As the global market for HPMC continues to expand, Chinese manufacturers are well-positioned to meet this demand. Their ability to produce high-quality, cost-effective products, coupled with their focus on innovation and sustainable practices, will enable them to maintain their leadership in the HPMC industry.

In conclusion, the rise of HPMC as a valuable compound in various industries is closely linked to the innovative capabilities and manufacturing prowess of Chinese manufacturers. As these companies continue to enhance their processes and product offerings, HPMC is set to become an even more integral part of the global supply chain. The future looks promising for this essential compound, and its applications will likely continue to evolve, driven by technological advancements and changing market needs.

-

Versatile Hpmc Uses in Different Industries

NewsJun.19,2025

-

Redispersible Powder's Role in Enhancing Durability of Construction Products

NewsJun.19,2025

-

Hydroxyethyl Cellulose Applications Driving Green Industrial Processes

NewsJun.19,2025

-

Exploring Different Redispersible Polymer Powder

NewsJun.19,2025

-

Choosing the Right Mortar Bonding Agent

NewsJun.19,2025

-

Applications and Significance of China Hpmc in Modern Industries

NewsJun.19,2025